Mechanical Seal Barrier Fluids

Fluorinated fluids specifically engineered to provide the safety and reliability required for the mechanical seals used in hazardous chemical processes and operations.

Halocarbon, a non-traditional, woman-owned small business contractor, supplies the metalworking industry with engineered synthetic fluids specially formulated to enhance machining capabilities and extend tool life. Headquartered in Georgia with production and R&D facilities in South Carolina, Halocarbon is poised to partner on future projects and solicitations, offering advanced solutions for your machining needs.

Halocarbon Mechanical Seal Barrier Fluids are fluorinated fluids specifically engineered to provide the safety and reliability required for the mechanical seals used in hazardous chemical processes and operations. For over fifty years, Halocarbon Mechanical Seal Barrier Fluids have been widely used across the petroleum, natural gas, and chemical industries. Halocarbon Mechanical Seal Barrier Fluids are designed for use in the sealing systems for centrifugal pumps, and rotary mixers and agitators. These high performance fluorinated fluids are nontoxic, nonreactive, nonflammable, and chemically inert, making them ideally suited for use in handling or processing fluids that are hazardous to operators or the environment.

| MSHV04 | MSHV06 | MSLV27 | MSLV56 | MSXT | |

|---|---|---|---|---|---|

| Viscosity (cSt) | |||||

| @ -20°C | 83.70 | 168.00 | 625.00 | 1715.00 | 147,600.00 |

| @ 0°C | 20.10 | 35.20 | 24.30 | 48.20 | 575.50 |

| @ 40°C | 3.90 | 5.80 | 3.06 | 4.72 | 16.47 |

| @ 100°C | 1.18 | 1.57 | 1.30 | 1.83 | 4.24 |

| Thermal Conductivity (W / m*K) | 0.065 | 0.065 | 0.066 | 0.066 | 0.071 |

| Flash Point (°C) | No Flash Point | No Flash Point | No Flash Point | No Flash Point | No Flash Point |

| Autoignition Point (°C) | No Ignition Point | No Ignition Point | No Ignition Point | No Ignition Point | No Ignition Point |

| Pour Point (°C) | -73 | -71 | -40 | -34 | 5 |

| Initial Boiling Point (°C) | ~200 | ~200 | ~255 | ~290 | ~330 |

| Vapor Pressure (torr, @ 40°C) | 0.5 | 0.4 | 0.013 | 0.010 | 5×10-5 |

| Density (@ 25°C) | 1.87 | 1.89 | 1.92 | 1.94 | 1.97 |

Halocarbon Mechanical Seal Barrier Fluids are synthetic fluorinated oils specifically formulated to lubricate and cool mechanical seal faces in rotary pumps, mixers and agitators. These fluids can be used in both pressurized and unpressurized systems that employ multiple seal arrangements (dual seal and tandem seal).

Halocarbon Mechanical Seal Barrier Fluids are intrinsically nonflammable and nonreactive. Unlike glycol-, alcohol-, hydrocarbon-, mineral oil-, or silicon-based barrier fluids, Halocarbon Mechanical Seal Barrier Fluids are chemically inert, making them ideally suited for use in applications that involve strong acids or bases, flammable solvents, hydrocarbons, corrosive chemicals, strong oxidizers, and reactive gasses.

Key Performance Characteristics

- Safe to handle, nontoxic

- Clean, no sludge formation

- Nonflammable (no flash or fire point)

- Low temperature fluidity

- High thermal stability

- Compatible with most metals, plastics, and elastomers

- Good heat transfer properties

- Excellent sealing and lubricating properties

Halocarbon Mechanical Seal Barrier Fluids not only allow you to achieve higher safety and reliability standards but also provide an industry-proven solution to mitigate the risk of seal-failures that could result in exposing hazardous process fluids to workers or the environment. Each Mechanical Seal Barrier Fluid can be formulated with an anti-corrosion additive to provide compatibility with a broad range of materials of construction.

Suitable for Use With

- Hydrofluoric Acid (HF)

- Hydrochloric Acid (HCl)

- Sulfuric Acid (H2SO4)

- Nitric Acid (HNO3)

- Phosphoric Acid (H3PO4)

- Silicon Tetrachloride (SiCl4)

- Chlorine (Cl2)

- Bromine (Br2)

- Oxygen (O2)

- Ammonia (NH3)

- Sodium Hydroxide (NaOH)

- Potassium Hydroxide/Lye (KOH)

- Hydrocarbon Solvents

- Natural Gas

- Propane

- Petroleum

- Aluminum Trichloride (AlCl3)

- Boron Trifluoride (BF3)

- Arsenic Trifluoride (AsF3)

When Lewis Acids are Involved, the Choice is Clear

Halocarbon Mechanical Seal Barrier Fluids are manufactured using Halocarbon PCTFE technology, which creates a chemical composition that is less complex and more cost-effective than barrier fluids produced using conventional PFPE-based technology. The inherent simplicity of PCTFE chemistry produces oils that do not contain any oxygen atoms in the chemical backbone. This feature makes Halocarbon Mechanical Seal Barrier Fluids more robust to attack by Lewis acids than PFPE (perfluoropolyether) barrier fluids, which are known to depolymerize when exposed to Lewis acids such as aluminum trichloride, iron or zinc chlorides, iron fluoride, and boron trifluoride.

In all cases, Halocarbon Mechanical Seal Barrier Fluids:

- underwent no weight loss

- did not experience a reduction in viscosity

- had no change in pH, and no increase in acidity

Test Conditions: Oils heated at 174 oC in the presence of 1.0 wt % anhydrous AlCl3 at 1.0 atm under N2 gas for 24 h. Pressure reduced to 0.1 mmHg to remove volatile organic compounds produced from decomposition.

Barrier Fluids for High Velocity Rotary Seals

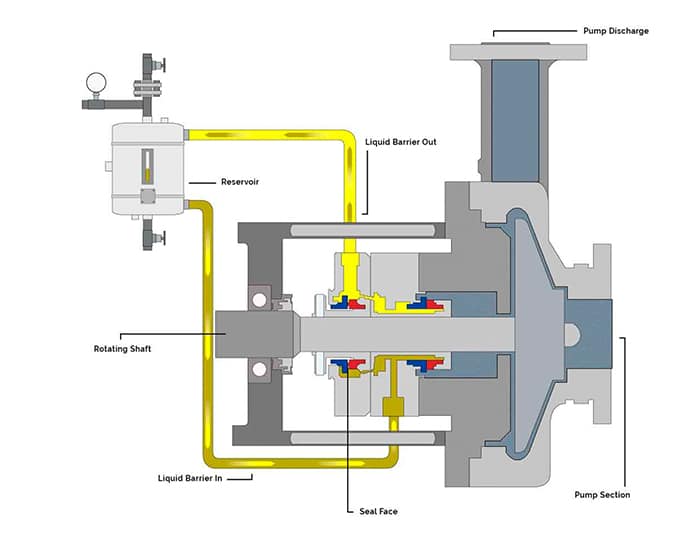

The schematic below depicts a typical piping plan for utilizing Halocarbon Mechanical Seal Barrier Fluids in the sealing systems for centrifugal and rotary pumps. These pump systems typically run at very high rotational velocities (typically 1200 rpm or 3600 rpm) and contain mechanical seals with small diameter/low surface area seal faces. Under routine operating conditions, it is critical that these seal faces are effectively lubricated and cooled. Halocarbon MSHV04 and Halocarbon MSHV06 can be efficiently employed to provide excellent lubrication of the seal faces and to provide convection cooling to maintain optimal seal face temperatures. These low-viscosity fluorinated barrier fluids are routinely used in high velocity centrifugal pumps to efficiently maintain seal face temperatures in the optimal operating range below 80°C (176°F) and are also effective for use in low-temperature applications

Barrier Fluids for Low Velocity Rotary Seals

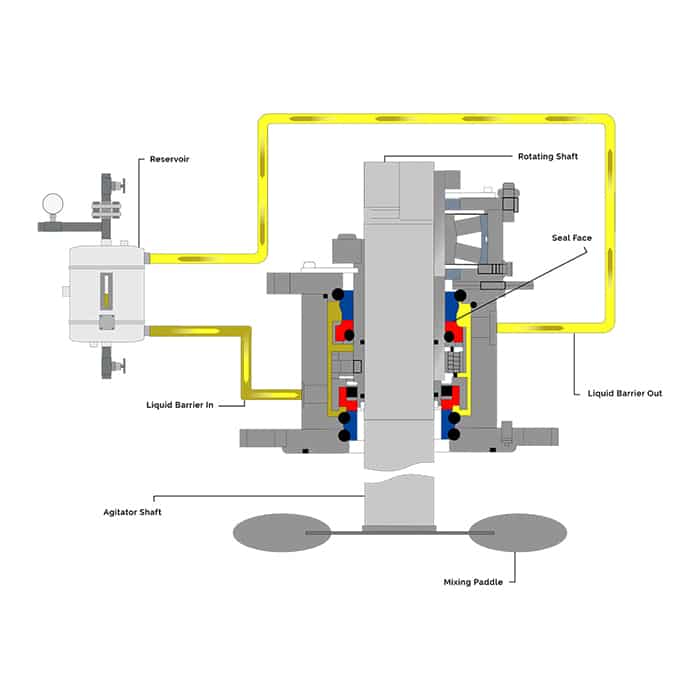

The schematic below depicts a typical piping plan for utilizing Halocarbon Mechanical Seal Barrier Fluids in the sealing systems for rotary agitators and mixers. This type of equipment is typically mounted vertically on a chemical reactor. In such equipment, the vertical shaft rotates at lower velocities (typically 150 rpm to 300 rpm) and contains mechanical seals with wider diameter/larger surface area seal faces. Under these less demanding operating conditions, the cooling of the seal face is of less importance relative to environment-side or process-side leakage. To address the challenges of chemical operations utilizing these types of equipment, Halocarbon has formulated oils with higher viscosities. Halocarbon MSLV27 and Halocarbon MSLV56 are designed for use in low velocity rotary systems to provide a low-leakage barrier fluid solution. Their higher viscosity also makes Halocarbon MSLV27 and Halocarbon MSLV56 suitable for use at higher operating temperatures.

Operational Seal Service Life Extension Fluid

Mechanical seals have the tendency to leak. In cases where these leaks occur at inopportune times, especially situations where critical chemical processes or operations cannot be stopped for maintenance of the mechanical seal, a solution is required to provide a short-term extension of mechanical seal life. Halocarbon MSXT is a high-viscosity PCTFE-based oil that can be effectively employed in combination with other PCTFE-based Halocarbon Mechanical Seal Barrier Fluids to extend the life of a mechanical seal to complete a critical operation in a safe and reliable manner. Halocarbon 700 Oil can be added directly to a barrier fluid reservoir to slow the leak rate of the barrier fluid into the process. In cases where the seal failure results in large openings to the process, the system will necessitate a shutdown to ensure safe operation. A Halocarbon Technical Representative can help you determine if Halocarbon 700 Oil is right for you.

Contact halocarbon

Corporate information

(470) 419-6364

customerservice@halocarbon.com

Corporate Headquarters

6525 The Corners Parkway, Suite 200 Peachtree Corners, GA 30092

Manufacturing Plant

1100 Dittman Ct North Augusta, SC 29841

Please let us know how we can help you by filling out the form below and clicking submit. Our helpful staff will contact you in a timely manner.