Tungsten is a hard and brittle metal that is difficult to machine using conventional methods. Its high melting point, low thermal expansion, and low electrical resistivity make it a popular material in various industries, including aerospace, defense, medical and energy. However, machining tungsten requires specialized techniques and equipment to ensure precision and efficiency. Halocarbon Metalworking Fluids are a family of best-in-class cutting and forming fluid technologies formulated with years of fluorochemical expertise. Our portfolio of metalworking fluids are designed to simplify tungsten machining processes.

In this blog post, we will cover:

- Types of Tungsten Machining

- Machining for Tungsten and its Alloys

- Cutting Fluids for Tungsten

- Forming Fluids for Tungsten

- The Benefits of Metalworking Fluids for Tungsten

Types of Tungsten Machining

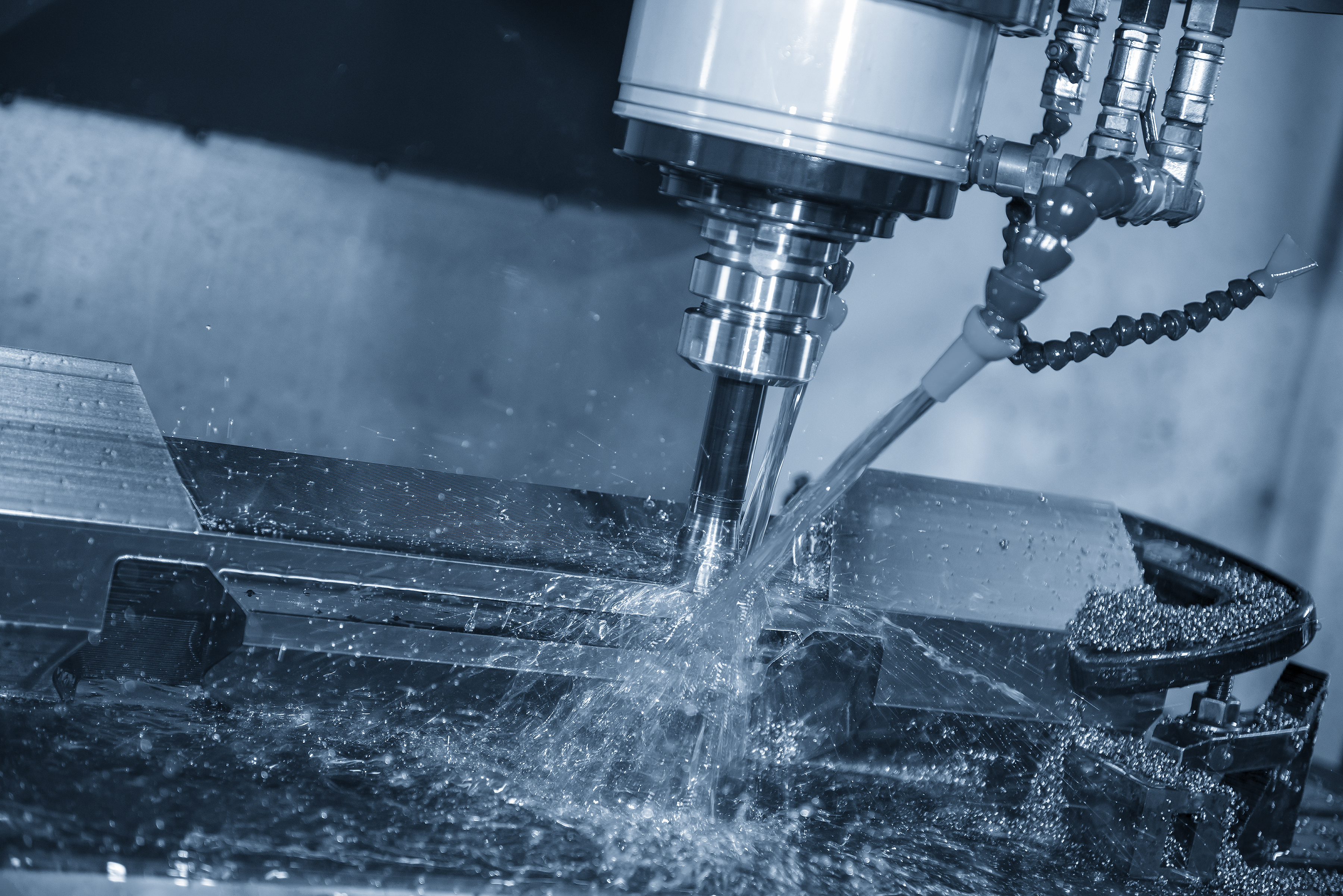

There are several types of tungsten machining methods, including turning, milling, drilling, and grinding. Turning is one of the most common processes used for tungsten machining, and it involves rotating the workpiece against a cutting tool to remove material. Tungsten milling, on the other hand, involves using a rotating cutter to remove material from the workpiece. Drilling is used to create holes in the tungsten workpiece, while tungsten grinding is used to create smooth surfaces or accurate dimensions.

Machining for Tungsten and its Alloys

Tungsten alloys are often used in high-temperature applications, such as rocket nozzles and aerospace components, due to their intrinsic thermal properties. These alloys are challenging to machine because of their high strength and low ductility. Machining for tungsten and its alloys requires a slow and steady approach to prevent cracking and chipping. Tungsten alloys also tend to work-harden, or become harder as they are deformed. As a result, tungsten alloys require sharp and sturdy tools and extremely high-performance fluids and lubricants to prevent excessive wear and tear.

Cutting Fluids for Tungsten

Cutting fluids are essential in tungsten machining to reduce heat and friction, improve tool life, and enhance surface finish. Halocarbon fluorinated cutting fluids for tungsten help prevent friction between working components, enabling faster processing and mitigating adherence of the metal to the tool. Additionally, our high-performance tungsten cutting fluids stabilize the temperature of the workpiece, which improves cutting precision and prevents built-up edge (BUE) on the surface.

Forming Fluids for Tungsten

Forming fluids are used in tungsten machining to improve the material’s formability and extend die life. These fluids are typically applied to the workpiece before or during the forming process to reduce friction and prevent the material from sticking to the tool. However, forming fluids can also affect the material’s surface finish, so it is essential to choose the right type of fluid for the application. Halocarbon’s selection of tungsten forming fluids helps ensure safety and reliability while improving workpiece surface finish and reducing product waste.

The Benefits of Halocarbon Metalworking Fluids for Tungsten

Halocarbon Metalworking Fluids, such as our cutting fluids and forming fluids, offer several benefits in tungsten machining. Our elite class of metalworking fluids is specifically designed to reduce heat and friction, which increases throughput while preventing damage to the workpiece and tools, mitigating replacement costs, downtime, and product waste. Additionally, our tungsten Metalworking Fluids enhance product quality with significantly improved surface finish and reduced occurrence of burrs and defects.

Halocarbon remains dedicated to developing high-performing, reliable metalworking fluids to provide optimum machinability and workability for tungsten metals and their alloys. Whether you’re seeking metalworking fluids for tungsten cutting, grinding, drilling, polishing, or milling, we ensure long-term fluid solutions for safe and effective processing. Looking to learn more or purchase a fluid? Contact us today!

Leave a Reply