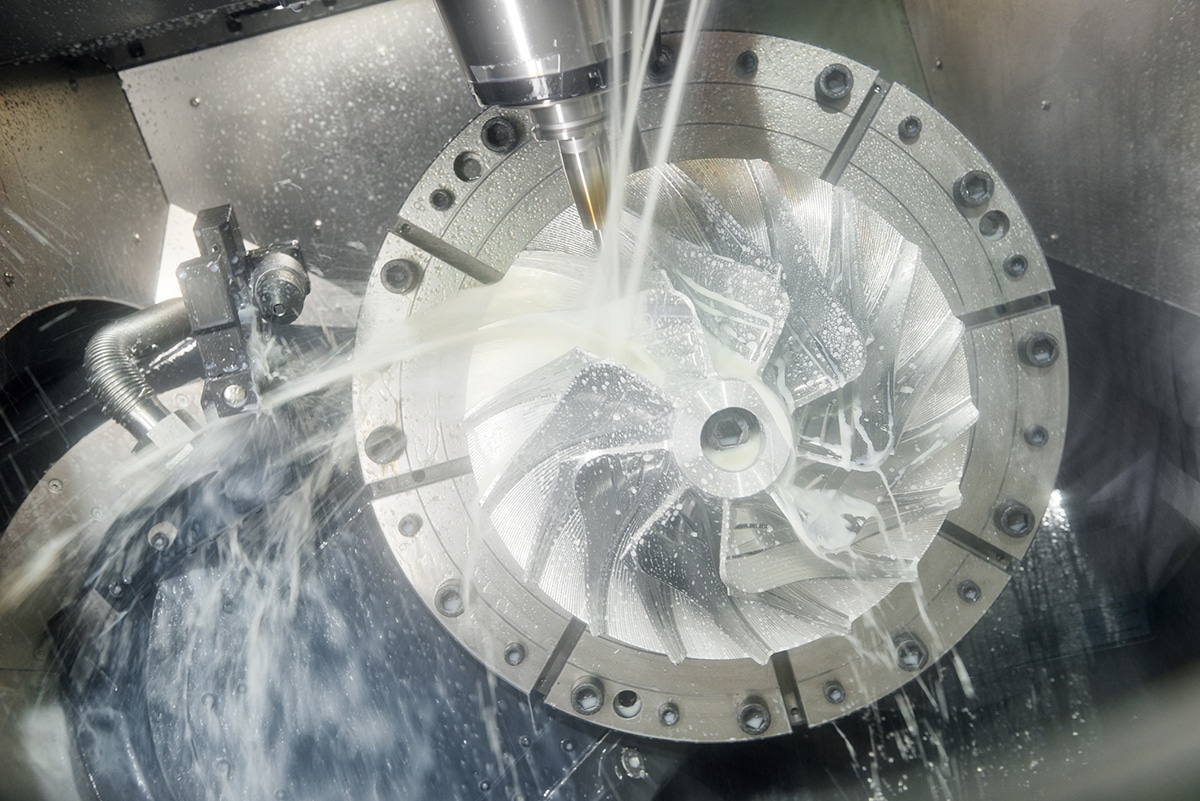

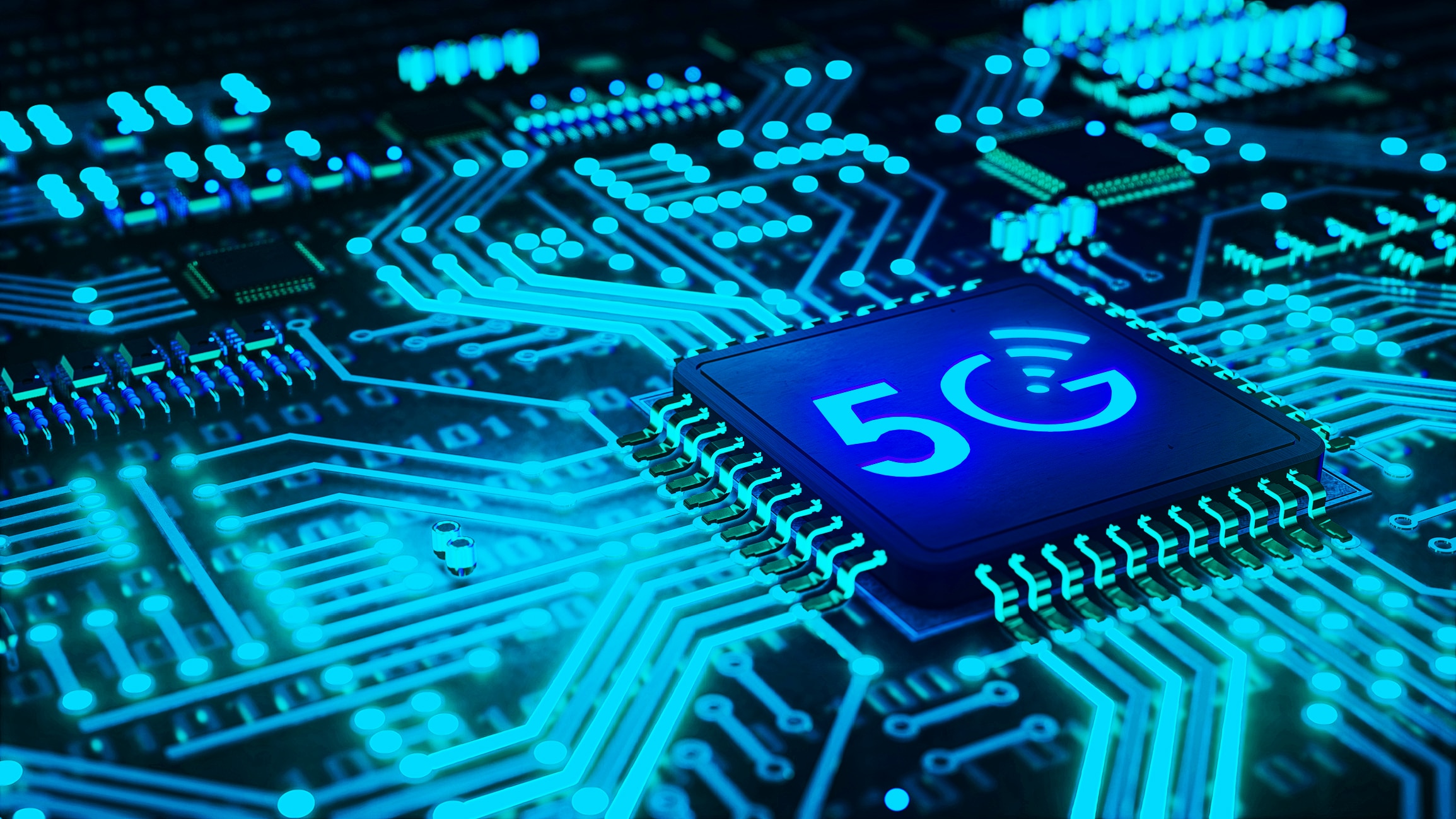

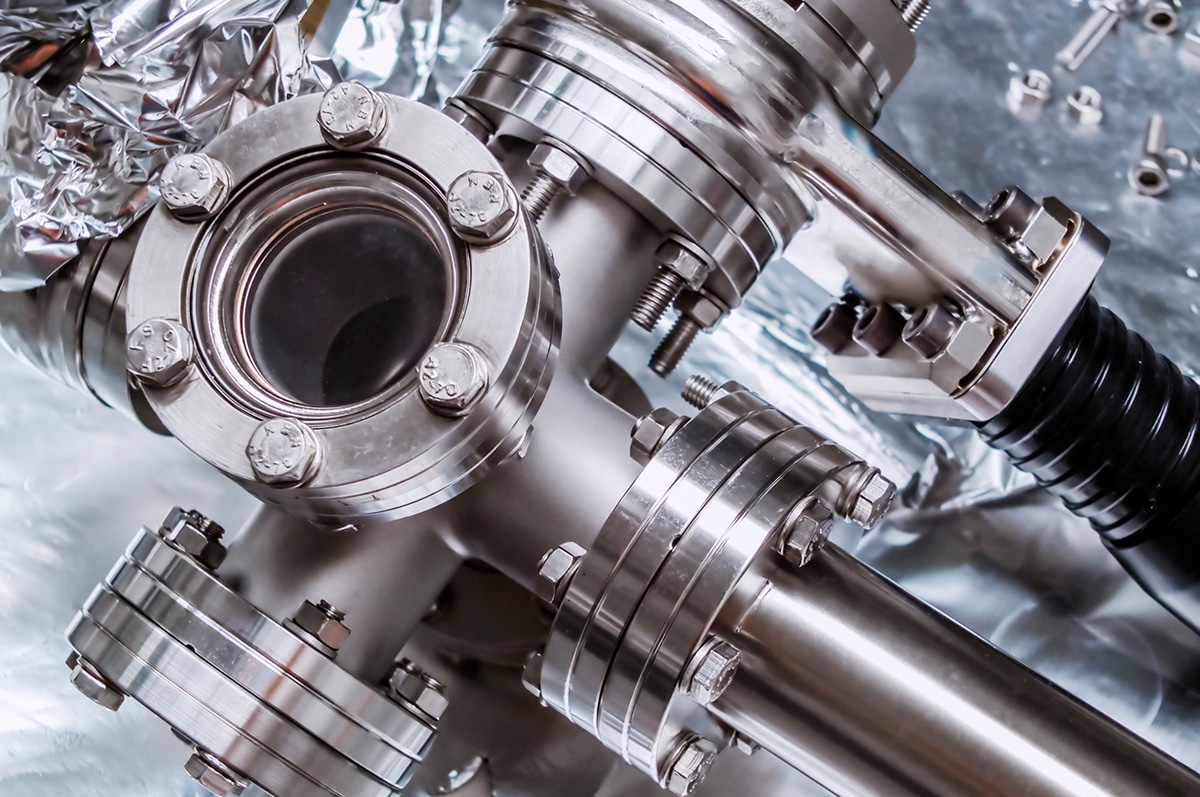

Semiconductor Packaging Materials with Halocarbon Electronics Solutions

With over a decade of experience, Halocarbon Electronics Solutions continues to accelerate the development of next-generation semiconductor packaging materials. By working closely with our partners, we leverage industry-wide expertise and resources to meet increasingly stringent requirements, overcoming the challenges and previously perceived limitations of the semiconductor fabrication industry. The critical role of Halocarbon Electronics Solutions